Hybrid & Electric Vehicle Corner

by: Curt Ward

Professor at Joliet Junior College

High-Voltage Electrical - An Important Part of the Lab Safety Lesson

As I write this article, the fall semester is off to a great start, and it is great to see all the new and returning faces in the classroom eager to learn. Every fall semester, our new students must complete a lesson on lab safety and pass a test before they are allowed to participate in lab activities. In this month’s article I will highlight some of the high-voltage electrical safety topics that should be covered as part of the safety lesson, regardless of whether hybrid and electric vehicles are part of the curriculum.

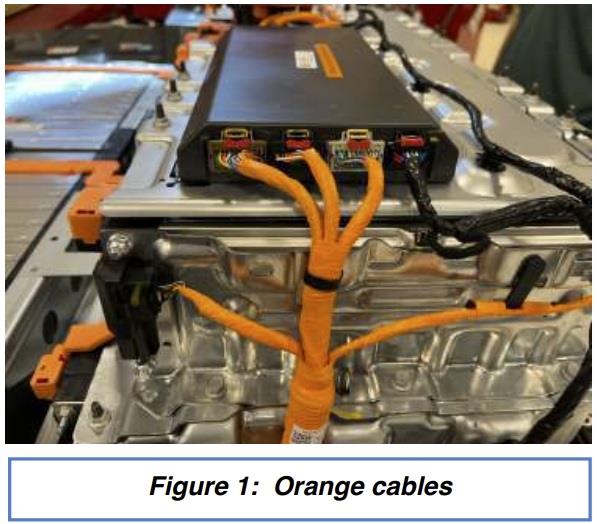

High-voltage circuits can be identified by the color of cables and the warning labels that are affixed to the various components. Any circuit that  has an electrical potential of greater than 60 volts DC or 30 volts AC will be identified by orange coverings or conduit (See Figure 1 – Orange cables). Unprotected contact with a live high-voltage circuit could result in serious burns, electrocution, or death.

has an electrical potential of greater than 60 volts DC or 30 volts AC will be identified by orange coverings or conduit (See Figure 1 – Orange cables). Unprotected contact with a live high-voltage circuit could result in serious burns, electrocution, or death.

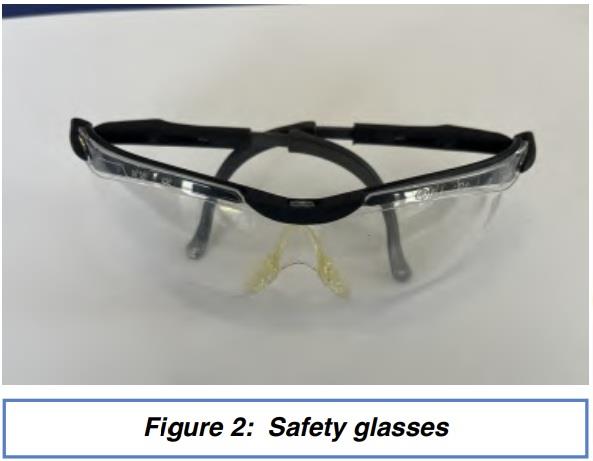

The proper use of personal protective equipment is the best way to protect oneself when working around high-voltage circuits. Eye protection must always be worn. The eye protection should have plastic frames, side shields, and meet the ANSI Z87.1 standard (See Figure 2 - Safety glasses).  Avoid any safety glasses that have a metal frame as they may be conductive and a shock hazard. Although ANSI rated safety glasses do not have an expiration date, they should be inspected before each use for scratches, cracks, or clouding, and replaced immediately if any damage is found, as this can compromise protection. For circuits greater than 400 volts, a full-face shield may be required.

Avoid any safety glasses that have a metal frame as they may be conductive and a shock hazard. Although ANSI rated safety glasses do not have an expiration date, they should be inspected before each use for scratches, cracks, or clouding, and replaced immediately if any damage is found, as this can compromise protection. For circuits greater than 400 volts, a full-face shield may be required.

High-voltage gloves are needed any time the potential exists for contact with a live high-voltage circuit.  The gloves must be rated at least 1,000 volts and class “)” by ANSI/ASTM. The gloves are date stamped and must be recertified six months after opening by a qualified glove inspection laboratory. Gloves that remain sealed in the package that they were shipped must be recertified after 1 year. A clean leather outer glove needs to be worn to protect the HV rubber glove from any material that might create damage and compromise the insulation properties. The gloves should be visually inspected and tested with a glove inflator before each use (See Figure 3 – Glove inflator).

The gloves must be rated at least 1,000 volts and class “)” by ANSI/ASTM. The gloves are date stamped and must be recertified six months after opening by a qualified glove inspection laboratory. Gloves that remain sealed in the package that they were shipped must be recertified after 1 year. A clean leather outer glove needs to be worn to protect the HV rubber glove from any material that might create damage and compromise the insulation properties. The gloves should be visually inspected and tested with a glove inflator before each use (See Figure 3 – Glove inflator).

Some manufacturers may have additional personal protective equipment requirements. Volkswagen, for example, requires an arc flash suit any time a technician is working on a high-voltage battery. Other manufacturers may require electrical hazard shoes or boots, insulated work mats or specific cotton work uniforms.

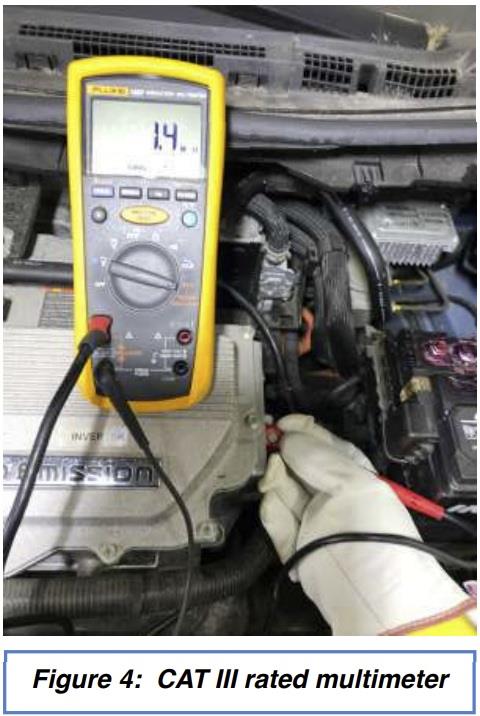

The digital multimeter and test leads used on high-voltage circuits should be category III rated at 1000 volts (CAT III). The International Electrotechnical Commission (IEC) establishes the standard to ensure the meter can provide accurate measurements of high-voltage circuits (See Figure 4 – CAT III rated multimeter). The failure to use the appropriately rated meter may result in inaccurate voltage reading and potential safety risk to the technician.

The digital multimeter and test leads used on high-voltage circuits should be category III rated at 1000 volts (CAT III). The International Electrotechnical Commission (IEC) establishes the standard to ensure the meter can provide accurate measurements of high-voltage circuits (See Figure 4 – CAT III rated multimeter). The failure to use the appropriately rated meter may result in inaccurate voltage reading and potential safety risk to the technician.

Although not required by all manufacturers, insulated tools such as ratchets, extensions, sockets, pliers, and screwdrivers provide an additional margin of safety when working around high-voltage components or systems. It should be noted there are both insulated tools and tools that have a non-conductive covering.

When hoisting a hybrid or electric vehicle it is important to refer to the manufacturers’ service information for the proper lift points. The incorrect placement of the lifting fixture may result in damage to the high-voltage battery or cabling.

A shop safety lesson is always a great way to start to the new school year. That lesson can become even more effective with the addition of high-voltage safety. This topic can be added to the lesson with minimal investment and does not require a vehicle. If you are looking for some additional ideas on this topic, refer to the ASE XEV level 2 certification standards at https://www.ase.com/ev/.

I will finish this article with the same offer I make after each of my presentations. If you are interested in getting started in the process of adding hybrid and electric vehicles to your curriculum or want more information, please feel free to reach out. I am more than willing to sit down in-person or online and share my experiences. Are you looking for a classroom textbook? Reach out to Pearson and ask for a review copy of the Electric and Hybrid Electrical Vehicle text that Jim Halderman and I co-authored. It is a comprehensive text covering all the latest information on the subject.